I acquired a broken MiniKorg (Univox badge, mode 700 single oscillator) as part of a deal selling a working Minikorg. The seller’s tech says it is not repairable. I don’t believe that. This is a lengthy process (for me!) so here is part one of the repair video. Part Two is in progress as I am troubleshooting as I write this.

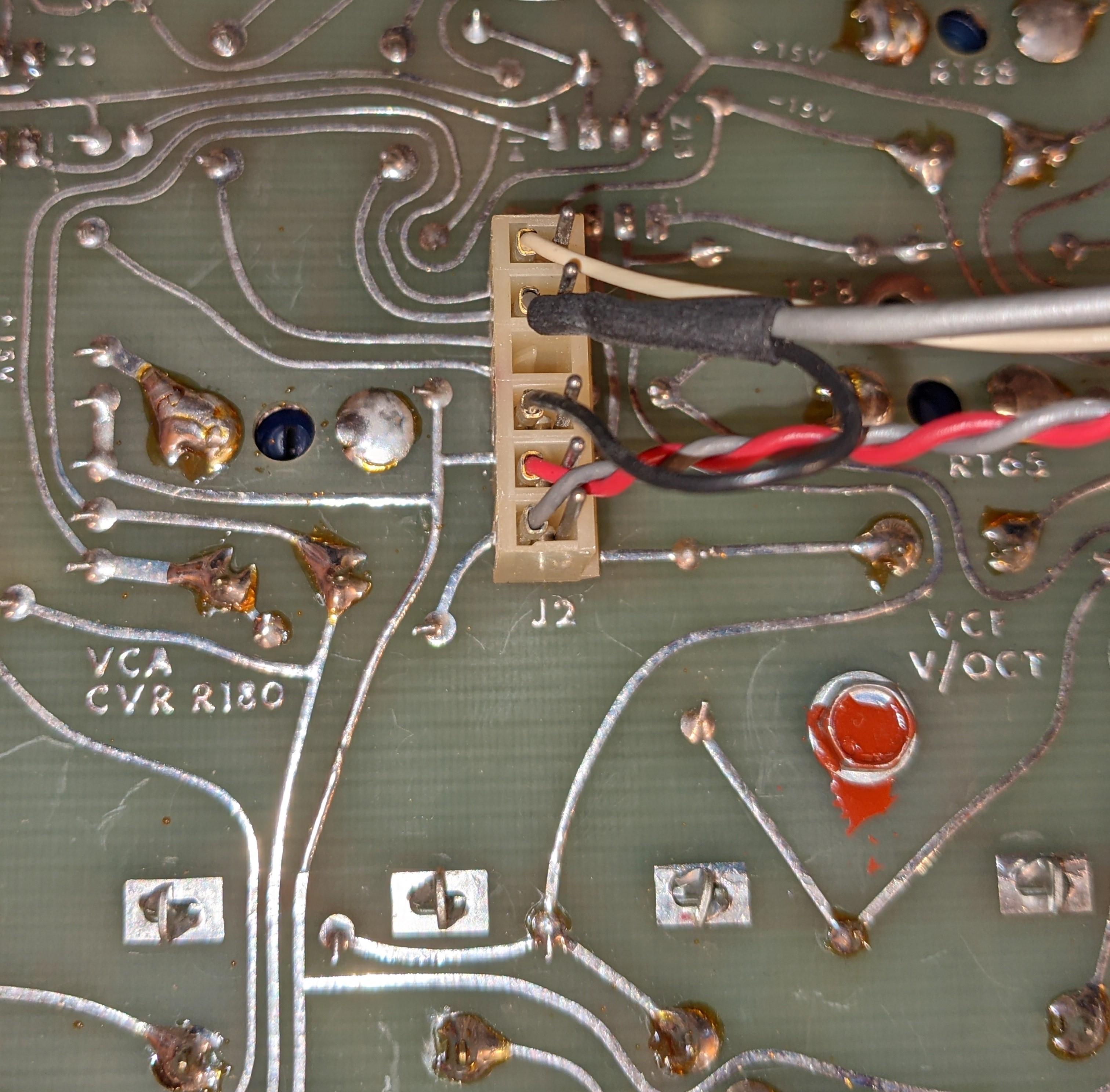

I opened it up and found the main oscillator was missing. This was no surprise since I was told it was bad. I had already bought a new one from https://enlo-1.com/ and installation was easy. They also sell filter replacements. Some other wiring was broken, probably because it was shipped to me with the oscillator circuit not mounted NOT MOUNTED. Yes, circuit boards flopping around breaks wires. I fixed the wires and tested the system.

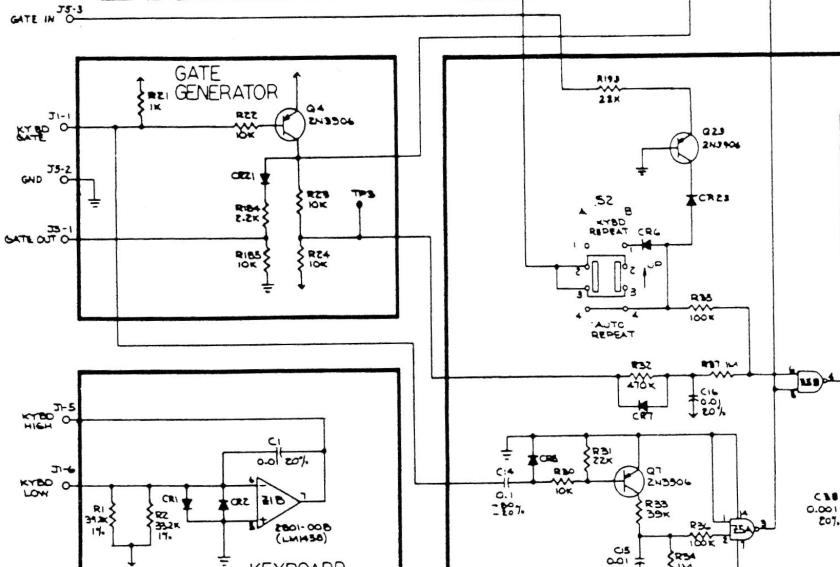

I could trigger notes, the filter and related controls work. Repeat works. Nothing related to pitch, other than changing the footage, worked. I only could play a single note- guessing the high C on the keyboard. I tested the voltage output from the keyboard for key presses and it produces increasing voltage as you moved up the keyboard, as it should.

I know the divider (MN133) is mostly working, since I hear octave changes from 2′ to 4′ to 8′ to 16′. I don’t hear a change from 16′ to 32′ this could be the switch or it could be the divider. Easy to check, since the divider produces outputs all the time. Just hook up a scope and read the output waveform and see if I have different ones where I should.

Hz/Volt

So how does the Korg Hz/Volt system work? The voltage range was about 11.5 volts. I don’t know the base frequency range of the VCO (what three octave range it plays in). The VCO frequency is proportional to the control voltage coming in. The voltage out of the keyboard doubles for each octave. In a Moog Volt/Octave system each octave change is just one volt.

Troubleshooting

CAUTION– BEFORE YOU BEGIN

This board is full of dangers; namely, several locations where AC is present up to line voltage (123VAC in my house)! The case is metal and it is the ground for the system. Touch either fuse holder lead, either power switch lead, or where the brown wire connects to the little bus by the transformer and you will be electrocuted (yes, injury or death can result) if you are touching the case or grounded some other way. Great case for the “one hand rule” which is keep one hand in your pocket while taking measurements while the synth is energized.

Some foolishly believe low-voltage household circuits can’t kill you. They can and do every year in the US. You can search for yourself, but here is a good report. https://www.cpsc.gov/s3fs-public/Electrocution-Report-2004-to-2013.pd

Extra risks for circuit board damage exist, too. Each board is mounted to the metal case, which is ground. If you power it on without the boards screwed down, all the leads along the edge of the board (under the wire bundle) run the risk of contact to ground, causing numerous short circuits.

This is why you ALWAYS open up and inspect a "for parts" or otherwise broken synth that came in the mail before powering it on. You can do much more damage than there already is.When screwed down, there is a gap between the solder joints and the case. Non-conductive standoffs would have been a better choice. I know of this problem because I did it and overheated an electrolytic cap (now replaced) until the magic smoke came out. If you do have to take reading on the bottom of a board, support it perpendicular to the case and clamped in place so it cannot fall on the ground case.

The fuse holder and power switch now have heat-shrink on the bare contacts. The best I can do for the transformer bus is glue on some cardboard.

NOW ON TO TROUBLESHOOTING…

I need to test the control voltage input to the VCO and see if it is changing or not. The VCO is fed a signal derived from the keyboard voltage output, and this controls the frequency that the oscillator outputs. The output range covers 3 octaves. Exactly which 3 is controlled by the footage selection.

I also need to check the VCO output. I believe it is pin 7. If the input CV signal is changing, I should see a changing output. I do not hear any changes, though, which is why I think the problem is upstream of the VCO. I hope that is the case and that I do not have divider problems (MN131) since those chips are hard to come by.

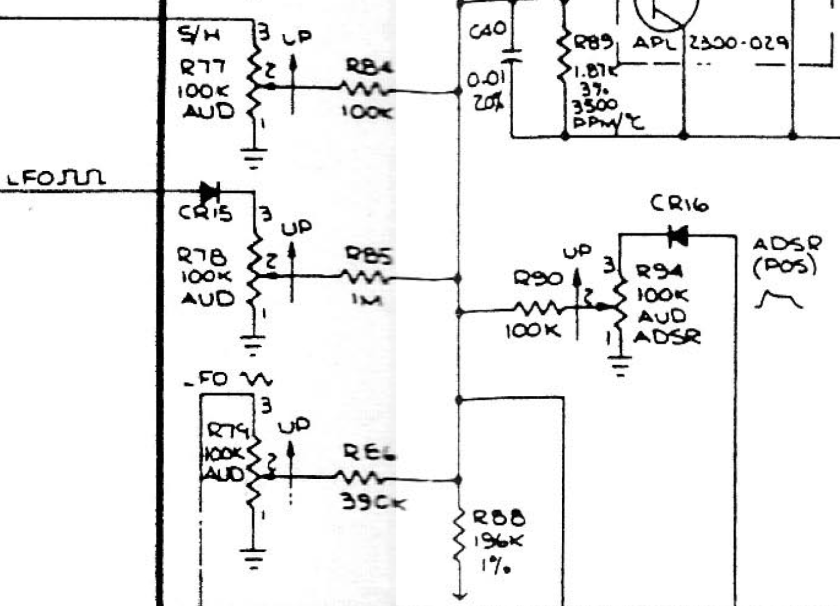

There is quite a lot of circuitry involved, and many inputs that affect the operation of the VCO. The Vibrato signal is an input to the VCO and affects the output. Portamento, Bender, and pitch control (tuning) also have inputs to the VCO. None are having any effect right now.

This block diagram of the synth is useful for troubleshooting and overall understanding.

I need to check the MN131A (or MN133- same function) divider outputs (pins 2, 3, 10, 11 are used). The input used is pin 9.

There are numerous numbered points on the circuit board. I can test wave shaping outputs, for example. I am optimistic further testing will narrow down the region of the circuit board causing the trouble.

Early Results

The 741 IC is working, though honestly appears to do nothing. The output voltage (pin 6) changes as you go up the keyboard, but is about the same voltage as the input. It is not exactly the same due to a 22KOhm feedback resistor. So what is this unity gain op amp for? Current control.

https://www.learningaboutelectronics.com/Articles/Unity-gain-buffer

In case you are wondering what pin is what in a TO-5 package, here you go. Pin 8 has the tab sticking out.

The CV input at pin 1 of the VCO also changes like it should. It comes from the 741. My VCO is brand new, so I think it is OK but will test with the o-scope.

The VCO output (pin 7) is a nice saw tooth of about 7v peak to peak.

I checked the frequency divider outputs (pins 2, 3, 10, 11) and I see properly divided signals! So where is the sound going??

Points 34/35 show the vibrato wave form and the speed and depth controllers alter it as they should. I also see pitch changes (for tuning) at point 31. Waveforms are at the following numbered points:

- 48 (saw)

- 49 (square)

- 50 (square with a little chorus or PWM- you can see the jitter on an o-scope)

- 55 (triangle)

When playing the keyboard all of these points output the sound perfectly. You can tap into the audio signal with a probe and give it a listen. Vibrato, Bender, Pitch and Portamento work. The signal is pre-filter, though, so no filter (or related effects like Bright or Expand) or volume control.

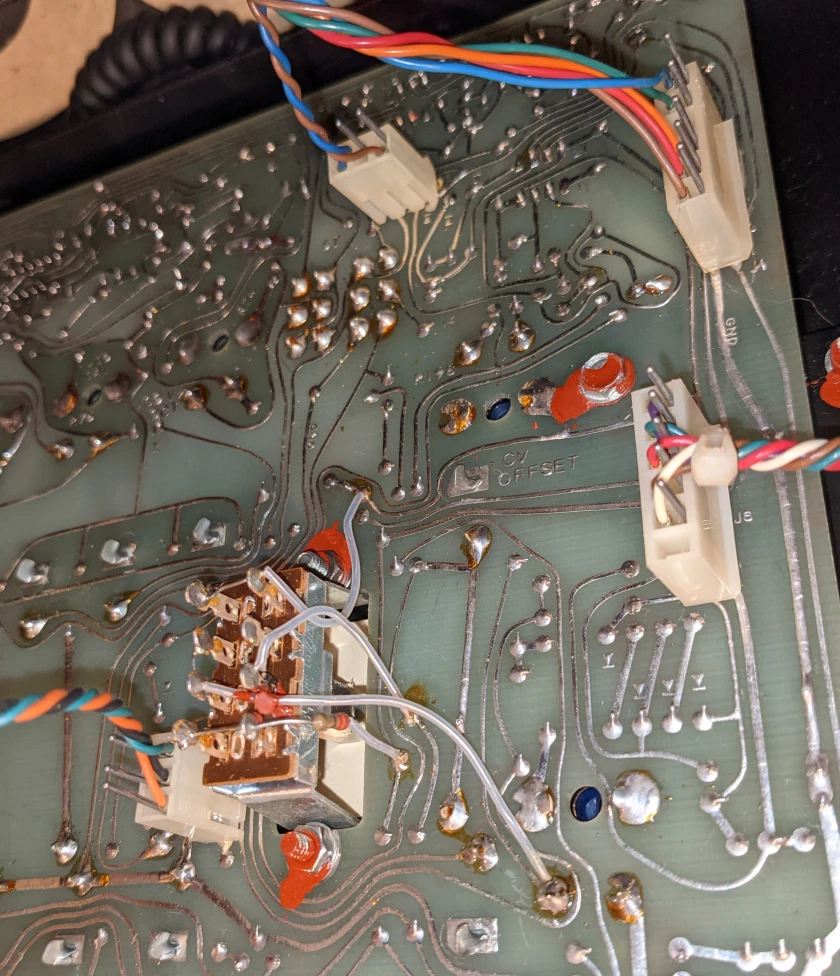

The signal leaves the oscillator board, goes through the mode (waveform) selector switch, and enters the filter board at pin 7. This short video shows the problem, and also demonstrates using an audio probe to listen to the sound inside the synth at various points. Point 11 (see main schematic) is the Repeat input to the filter board.

Exploring the Filter Board

I now know the problem is on the filter board. As you can see from the block diagram, the filters are sequential: high-pass then low-pass and into a VCA made of discrete components.

I believe the VCA is fine. The envelope generator controls (Sustain, Attack, Percussion, Singing) all cause the expected volume changes. When you turn on Expand, the envelope is applied to both filters, and that works, too. The sound from the VCA also responds to moving the traveler knobs (the filter controls).

The low-pass filter “IC” has already been replaced. The high-pass is original. There are other components on the board, though, for controlling the filter, so the problem may not be in a filter IC.

The filter chips are the SAME, they are just set up differently. There are some resistor changes and the input is changed! Instead of pin 5, it is pin 4.

Pin 1 is the CV input from the associated traveler. Pin 6 is feedback. Pin 5 is the audio signal input. Pin 8 is the filter output. There is an unlabeled test point in the upper left corner of the filter board- this is the output signal on its way to the VCA circuitry. This should be enough information for me to listen in at those points and see where the audio is changing from my nice input to a single pitch no matter the key press.

The main output from the filter board is at point 23. Point 4 is the Expand input from the envelope generator.

There is one more thing that bothers me- the role of point 53. It is connected to scale selection and you can see it in the filter diagram. I think it may be a bias for key tracking. Change the footage, change the bias to the filter. I tested this and found the voltage changes with different footage from 18 to 20v. So this is working.

I lifted the filter board so I could test the readings in and out of the ICs. The input and output of the high-pass filter are good. You can also filter the signal using the traveler as expected. The inputs are hard to find, but pin 2 does has a signal that varies in pitch with key presses. Pin 6 has no real pitch control but responds to filtering. Pin 4 is like pin 6, but not as loud. Nothing from pin 8. I have a hunch that the schematic is wrong. I think 6 is the output, 4 is the feedback, and 2 the input on the low pass filter. I decided to crank up my amp and give a closer listen. The main output DOES vary with key presses, but only when the LPF is closed, and you just get a DTMF type sound. The dominant signal, which does not change with key presses, becomes stronger as you open the filter.

This post got really long, so you will have to read Part Two for the remaining electronic repairs.

Key Repair and Key Cleaning

One key was broken during shipping. I was able to splint it and glue the broken piece bad on. I keep odd bits of plastic, wood, and metal around for jobs like this. I have found that vintage synths often require some non-electrical work to the case, keys, and circuit boards. A Dremel is also a key tool for making or repairing parts.

I inserted some wood and a bit of sandpaper as a shim to make it fit tight while the glue dried. The little vice is awesome and can move in 3 dimensions!

Cleaning is not hard, just a little tedious. I use a car care cleaner designed for plastics. It can also remove craze from metal. A microfiber cloth and a nylon bristle brush handle the cleaning.

**BONUS CONTENT**

More Electrical Safety

Don’t let your body be a path for current flow from the line voltage to ground. Ground in this case can be the metal case, or simply the ground you are standing on.

Why is the fuse on the hot (line current) wire? If the fuse blows, the circuit is de-energized since the hot line current does not pass through the fuse. If the fuse is on the neutral (return) line, then the circuit is still energized even if the fuse is blown, and can shock you. It won’t operate since there is no return path for current, BUT THERE IS LINE VOLTAGE STILL AT THE SWITCH AND TRANSFORMER (if you turned it on). IF YOU TOUCH THEM WHILE GROUNDED YOU BECOME THE PATH FOR CURRENT FLOW.

If a fuse keeps blowing, don’t keep replacing it. Figure out the cause and fix it.

Building a Replacement Frequency Divider

If you need a new MN131 or MN133, the parts are rare and expensive. https://shop.smelektronik.ch/pi/en/IC-out-of-production/IC-for-Musicinstruments1/IC-Music-Keyboards-Organs1/ic-music-mn131a.html

A frequency divider is a common circuit. Problem is knowing the specs, like output voltage range. Some smart guys may have figured it out. The following is from https://sub-continental.com/diy_eng.html#minikorg

MN133 and MN131A are very rare and obsolete frequency divider integrated circuits, they are very difficult to find or at an insane price. Here’s a little substitution circuit that will allow you to make your MiniKorg 700S synth octave divider work again with a CD4024BE IC and few transistors. You will have to unsolder and remove the MN133 (or MN131A) from the board, to remove the two 33K resistors (crossed out in red on the schematic) and to wire the circuit as indicated. The 2K trimmer for the LM317LZ adjustment will allow you to trim the right sawtooth waveform for all the octaves.

One last important thing is that you need to use a shielded wire for the signal that is drawn in purple in the schematic.

Some tips on this diagram. 7’s have slashes through them (European style). 1’s almost look like an upside down ‘V’. The Vreg points all come together to a single joint; this is how the circuit and CD4024 is powered from the LM317. The voltage input to the LM317 is the 20V positive rail of the synth.

Smoke Test

Smoke Test